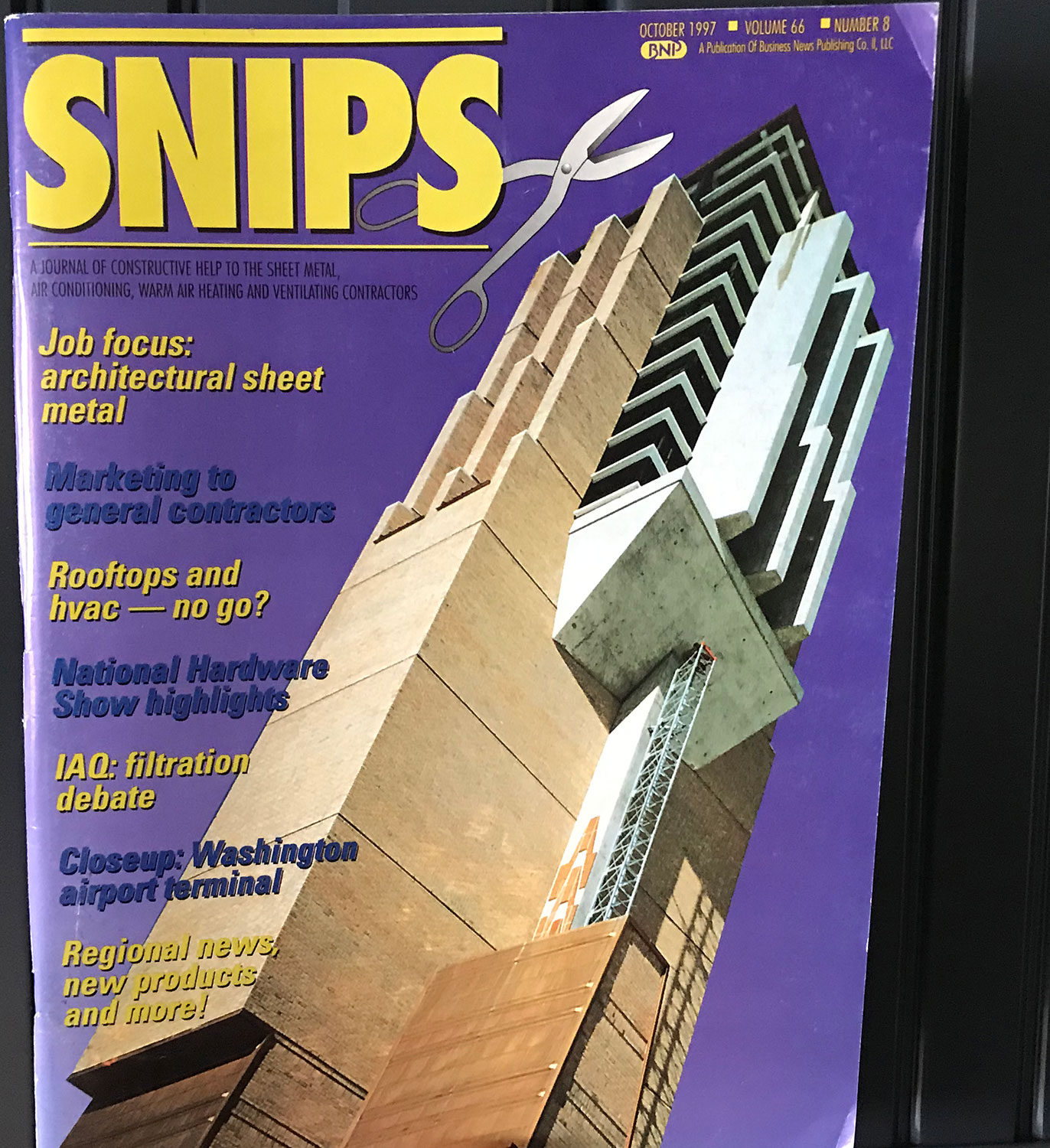

Laurie Bell Tower – U of M Campus – Ann Arbor, MI

Ann Arbor, MI – Sixty beautifully engraved bronze bells from the Netherlands are just one part of a magnificently crafted tower recently finished on the grounds of the University of Michigan North campus here.

This is an unusual structure in more ways than one. Detroit-based Custom Architectural Sheet Metal Specialists Inc. (C.A.S.S.) crafted 400 sheet of 20 oz. copper in the roof and flat seamed siding, as well as decorative A-shaped panels surrounding the tower.

This job required close cooperation and quite a bit of inspiration among those involved, from architect to craftsmen.

“Beautiful workmanship” is how many people describe the finished project.

Seven-year-old CASS’s work is 100% architectural sheet metal. On a recent visit by SNIPS, the shop area was empty, a sign that its 13 employees were busy working outside on some of Detroit’s highest profile building projects. Another example is the recent restoration of the 100-plus year old Saint Anne’s church on the city’s far south side.

“The most rewarding thing about being an architectural sheet metal contractor is meeting and conquering challenging projects that carry a difficulty level far in excess of the normal day-to-day metal roofing business,” Parvin said. He is a member of SMACNA’s Architectural Sheet Metal Council steering committee and will discuss some of the company’s more note-worthy efforts at the October convention in Las Vegas.

The bell tower used 4,000 one-inch brass acorn nuts at about $6 a piece: some serve as anchors into the concrete, while others are merely decorative and much in the way of hand work to accomplish. A special form had to be fabricated to hold the screws in position as they were leaded and soldered into place.

Also innovative was the way the workers tackeled the 200 foot tower, often using scaffolding and a rig called a Scan Climber. There’s nary a square corner in the tower, which complicated the layout procedure – all angles of the inner arch are skewed, as well as two ceramic niched set into the pillars.

There’s nary a square corner in the tower, which complicated the layout procedure – all angles of the inner arch are skewed, as well as two ceramic niched set into the pillars.

A laser benchmark had to be used to establish true vertical liunes for the A-panels. Some of the bells weigh as much as 8,000 pounds, and were made by Royal Eijsbouts, which also built the stainless steel control system for the bells and their structural steel supporting frame. The Robert H. Lurie Memorial Tower was built at a cost of $5 million, dedicated to the memory of Robert H. Lurie, a U of M school of engineering alumnus who made a fortune in real estate. He renovated many older buildings in the area and at one time was a owned of the Chicago Bulls.

Toronto based Ellis-Don Contruction was the general contractor on the job. The tower itself is cast in place concrete, with brick veneer supported on galvanized steel relief angles.

Parvin credits the leadmen on the project for its success. Greg Gietek, project manager/estimator, had to sift through a complex set of drawings picking out pieces of copper at different levels that were difficult to find, let alone create a hard labor and material bid. “There was nothing missed on this project.” The craftsmen were led by 43-year veteran Eugene Lovasz and 30-plus year man Ed Skowron. The company’s field is directed by vice president Chet Klos, a 40-year sheetmetal craftsman.