Foiling the Copper Thieves

C.A.S.S. not only obtained the contract for roof renovation but the demolition contract for the entire interior, as well. The complex nature of the project compelled C.A.S.S. to request an expansion of its scope of work beyond the copper roofing trade. C.A.S.S. asked to assume responsibility for demolishing the two towers down to the roof, removal of the skylight forming the ridge of the roof, and providing temporary cover for the skylight and exposed gaps in the deck. “We believed coordination and responsibility issues could be complicated in terms of temporary weather protection in terms of infilling the gaps of the wood decking after tower removal.” said Parvin.

The removal and replacement of existing electrical and fire suppression systems added another layer of complexity to the job. “Who would handle the de3ck repairs necessary at the approximately 100 electrical boxes being removed and infilled with exposed finished wood decking?” said Parvin.

For efficiency and better control, Campbell/Manix then turned over the entire tower and interior demolition to C.A.S.S. “This was a first for C.A.S.S.,” said Parvin. “We demolished two existing canopies and the two 70-foot towers from above the roof to the concrete interior floors. We saw cut the concrete floors, removed the carpet, and demolished the altar. We also removed the existing electrical systems and infilled the decking at the locations of the removed lights.”

With the aid of Connelly Crane Rental Corp., Detroit/Redford and Holt/Lansing, C.A.S.S. began tower demolition in late October 2007. Parvin and John Martin, C.A.S.S. foreman, met with Denny Connelly of Connelly Crane to plan and execute the demolition. “Demolition of the towers took two days and the wood decking infill another two days,” said Parvin.

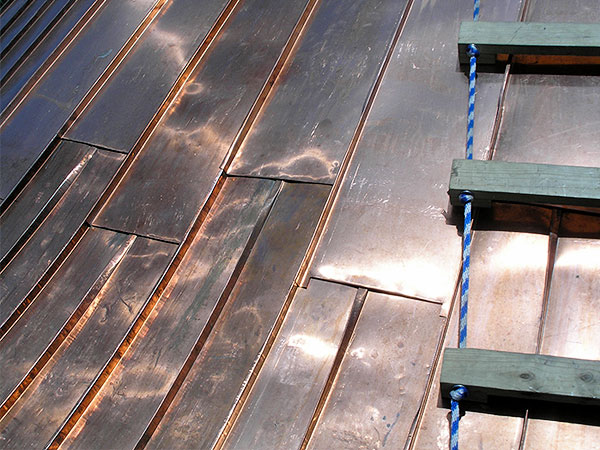

In tearing off the old copper roof, C.A.S.S. worked with Campbell/Manix in selecting a recycling company, H&H Metals, Inkster, MI, to recycle approximately 20,000 lbs. of the old copper. “Approximately $35,000 to $50,000 in recycled copper was returned to the parish,” said Parvin. “As a theft-prevention strategy, H&H Metals used a locked dumpster with a thousand pound lid that could only be lifted with big equipment. Plus, the copper was removed on a weekly basis. All in all, H&H Metals had the best game plan to keep the copper secured.

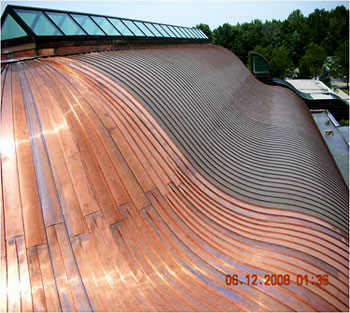

C.A.S.S. also partnered with George I. Landry, Inc., a Milford-based carpentry contractor selected by Campbell/Manix, Inc., to build a carpentry roof structure over the existing deck. “The structure is a new 2×8 wood framing and plywood lattice system designed to encapsulate new electrical and sprinkler systems, as well as house a foamed-in-place insulation system,” said Parvin. “Placed over the lattice system, the new wood deck consists of two layers of 3/8″ plywood staggered, glued and screwed to form the new curved roof system.”