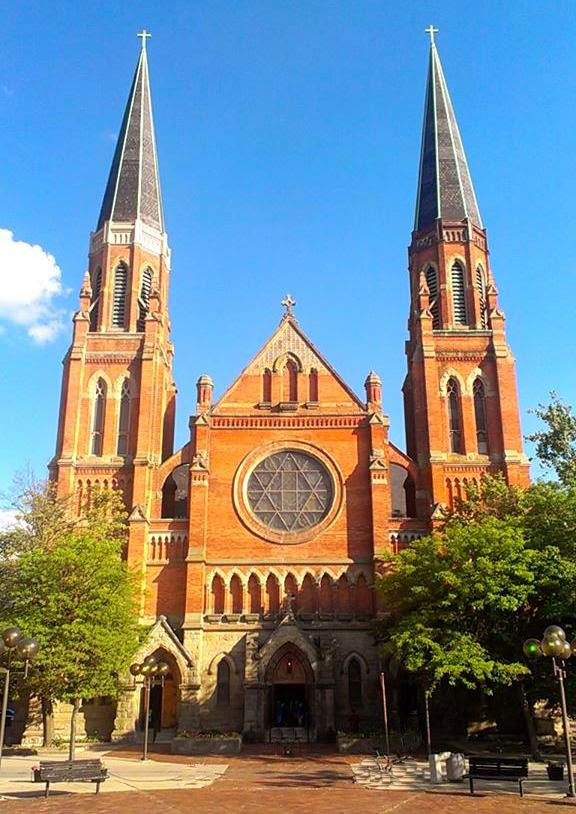

Originally built in 1886, Saint Anne Church is one of south Detroit’s most well-known landmarks. It is classic Gothic Revival, but suffered from extensive weatherization and deteriorization from hot summers, rainfall and cold snowy winters. The building also suffered from several piecemeal and occasionally haphazard restoration efforts.

The goal was to complete the project before the parish’s 300th anniversary in 2001. The church holds the birth records for the daughter of Antoine de la Mothe Cadillac, the European credited for establishing Fort Detroit.

It began with a one room log cabin on July 24, 1701, according to church records.

“The major challenges of historical restorations are caused by the duplication process, according to Glenn Parvin of Custom Architectural Sheet Metal (CASS). “Because by definition, on restoration jobs duplication is critical.”

There were no engineering drawings to follow, no architectural renderings – instead, much of this work was done by intuition and careful exploration, those common tools the original craftsmen used in first creating this house of worship.

Restoration was estimated at $4 million, and wound up taking an entire year. The heights involved represented yet another challenge, with workers often up to 110 feet off the ground.

“The reconstruction of the ogee tracery presented the greatest challenge,” Parvin said. “CASS had to find a way to make a compound ogee curve. The easiest way of describing this might be to imagine an inflated bike tire and the curves created. A tire is rounded at its cross section as well as its circumference. Now, think about making sheet metal do this.”