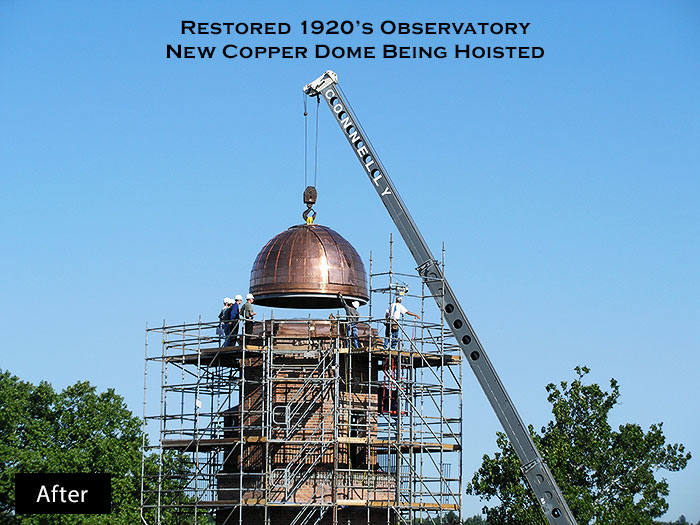

Working with a daunting schedule, CASS Sheetmetal custom fabricated and installed a shiny new, historically accurate copper cupola on top of the Cranbrook Observatory Tower, a national historic landmark in Bloomfield Hills, MI.

“This was an extreme task that involved much cooperation and effort between our subcontractors and the trades,” said Glenn Parvin, CASS Sheetmetal president. “we kept to a tight schedule.” The company’s challenge was to complete and install the dome in two months working around the community’s summer calendar.

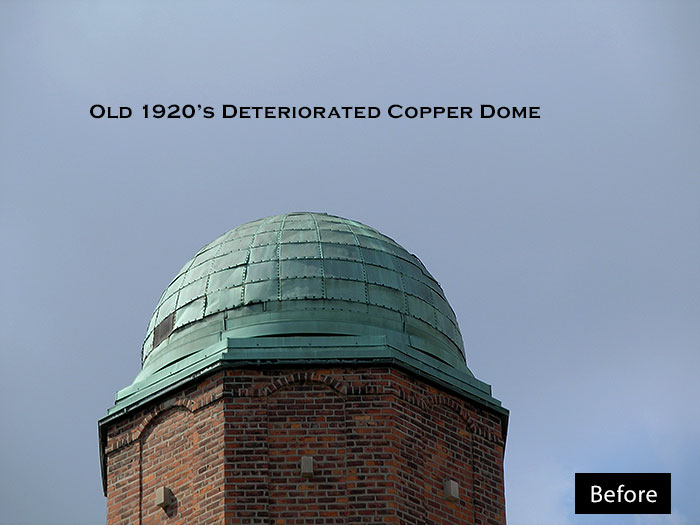

The work was part of a combined project to rebuild the tower’s deteriorating copper cupola and to restore the Ludowici clay tile roof of the Cranbrook Library, both part of the venerable Cranbrook Educational Community. The tower was built in the 1920’s and originally served as a functioning observatory. The years and weather had taken their toll on the structure. Its existing copper cladding, which was simply riveted to the structural steel, had leaked for years..